Understanding PCBA Assembly: A Comprehensive Guide for Professionals

2025-08-21

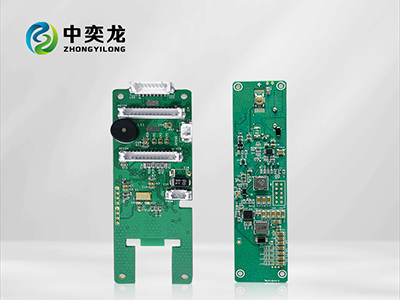

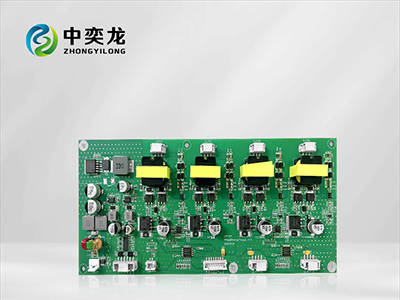

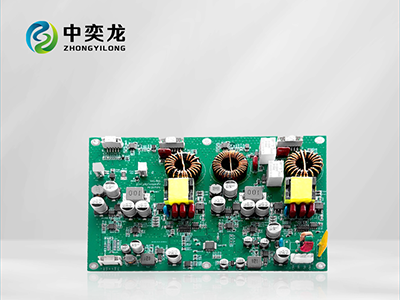

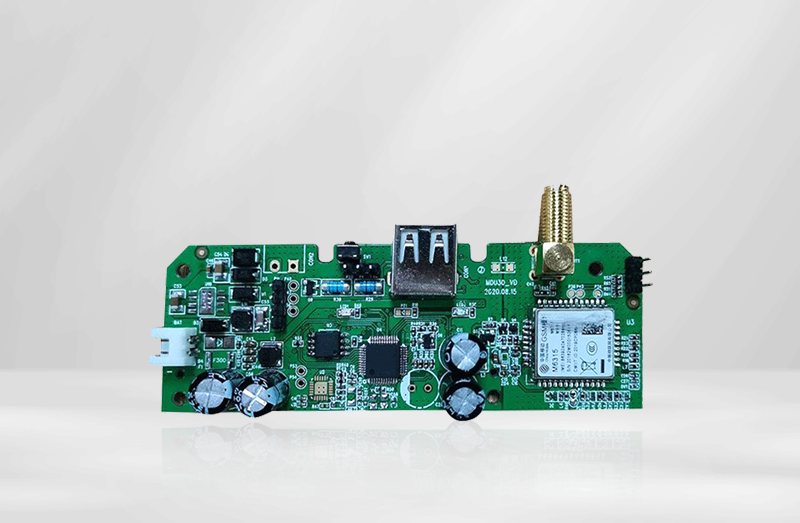

PCBA (Printed Circuit Board Assembly) is a crucial process in the electronics manufacturing industry, involving the assembly of electronic components onto a printed circuit board (PCB). This process transforms a bare PCB into a functional electronic device. Understanding PCBA assembly is essential for professionals involved in electronics design, production, and quality assurance, as it directly impacts the performance and reliability of the final product.

The PCBA assembly process typically consists of several key stages. First, surface mount technology (SMT) is often employed to place components onto the PCB. In this stage, tiny electronic components, such as resistors and capacitors, are mounted directly onto the surface of the circuit board. This method has gained popularity due to its ability to accommodate smaller components and higher component densities, allowing for more compact designs.

Following the SMT phase, the next step is soldering. This can be accomplished using various techniques, including reflow soldering and wave soldering. Reflow soldering is commonly used for SMT components, where the board is heated in a controlled manner to melt solder paste that has been applied to the pads on the PCB. Wave soldering, on the other hand, is typically used for through-hole components, where the PCB is passed over a wave of molten solder to create strong electrical connections.

Once soldering is complete, the assembly undergoes inspection and testing. Automated Optical Inspection (AOI) systems are often employed to detect defects such as misplaced components or soldering errors. In addition, functional testing may be performed to ensure that the assembled board meets design specifications and operates correctly. Quality control is paramount, as flaws at this stage can lead to product failures in the field.

Moreover, the importance of selecting the right materials cannot be overstated. The choice of PCB substrates, solder types, and component specifications can significantly affect the final product's performance. For example, high-frequency applications may require specialized materials to reduce signal loss, while temperature-sensitive components may need specific soldering techniques to prevent damage during assembly.

In conclusion, understanding the intricacies of PCBA assembly is vital for anyone involved in electronics manufacturing. From the initial component placement to the final testing of the assembled board, each step plays a critical role in the production of reliable electronic devices. By mastering the PCBA assembly process, professionals can contribute to creating high-quality products that meet consumer expectations and industry standards.

The PCBA assembly process typically consists of several key stages. First, surface mount technology (SMT) is often employed to place components onto the PCB. In this stage, tiny electronic components, such as resistors and capacitors, are mounted directly onto the surface of the circuit board. This method has gained popularity due to its ability to accommodate smaller components and higher component densities, allowing for more compact designs.

Following the SMT phase, the next step is soldering. This can be accomplished using various techniques, including reflow soldering and wave soldering. Reflow soldering is commonly used for SMT components, where the board is heated in a controlled manner to melt solder paste that has been applied to the pads on the PCB. Wave soldering, on the other hand, is typically used for through-hole components, where the PCB is passed over a wave of molten solder to create strong electrical connections.

Once soldering is complete, the assembly undergoes inspection and testing. Automated Optical Inspection (AOI) systems are often employed to detect defects such as misplaced components or soldering errors. In addition, functional testing may be performed to ensure that the assembled board meets design specifications and operates correctly. Quality control is paramount, as flaws at this stage can lead to product failures in the field.

Moreover, the importance of selecting the right materials cannot be overstated. The choice of PCB substrates, solder types, and component specifications can significantly affect the final product's performance. For example, high-frequency applications may require specialized materials to reduce signal loss, while temperature-sensitive components may need specific soldering techniques to prevent damage during assembly.

In conclusion, understanding the intricacies of PCBA assembly is vital for anyone involved in electronics manufacturing. From the initial component placement to the final testing of the assembled board, each step plays a critical role in the production of reliable electronic devices. By mastering the PCBA assembly process, professionals can contribute to creating high-quality products that meet consumer expectations and industry standards.

Related News

WhatsApp

WhatsApp

E-mail

E-mail