PCB Manufacturing Services

It offers small and medium mass production PCBS, which can produce boards of 1-32 layers. With 15 years of production experience, we provide service for more than 100 countries and tens of thousands of customers around the world, quality assurance!

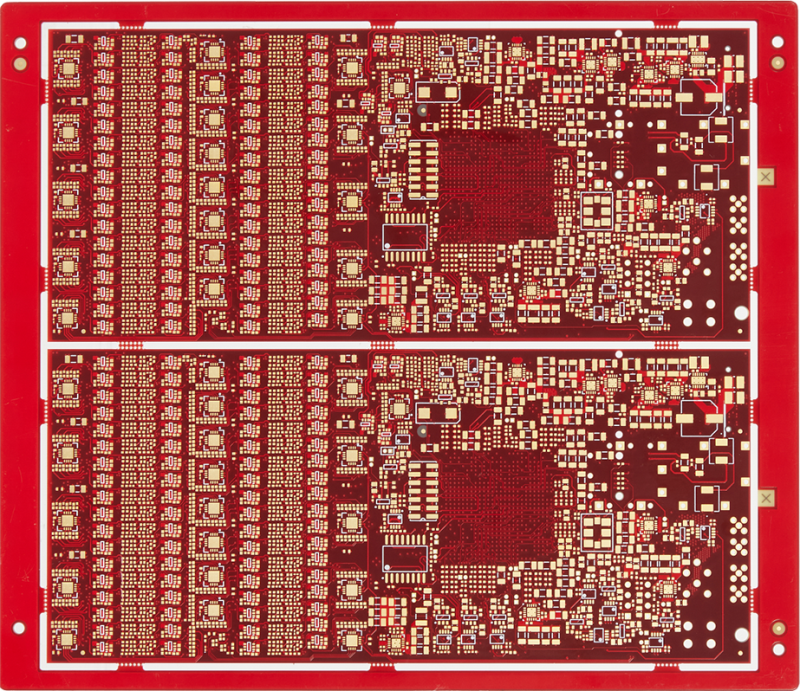

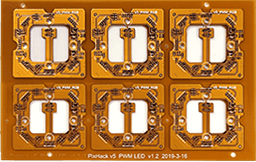

Multilayer PCB

Product application: Clean technology, etc. 1~32 layer PCB board Hole copper :20um Watch copper :35um Plate thickness :1.6mm Minimum aperture :8mil Mechanical hole :0.2mm Line width/line distance :8mil Surface treatment: heavy gold

Special process requirements

Special process requirements Provide PCB special process customized production services Strong engineering team support Advanced production equipment to meet the process requirements

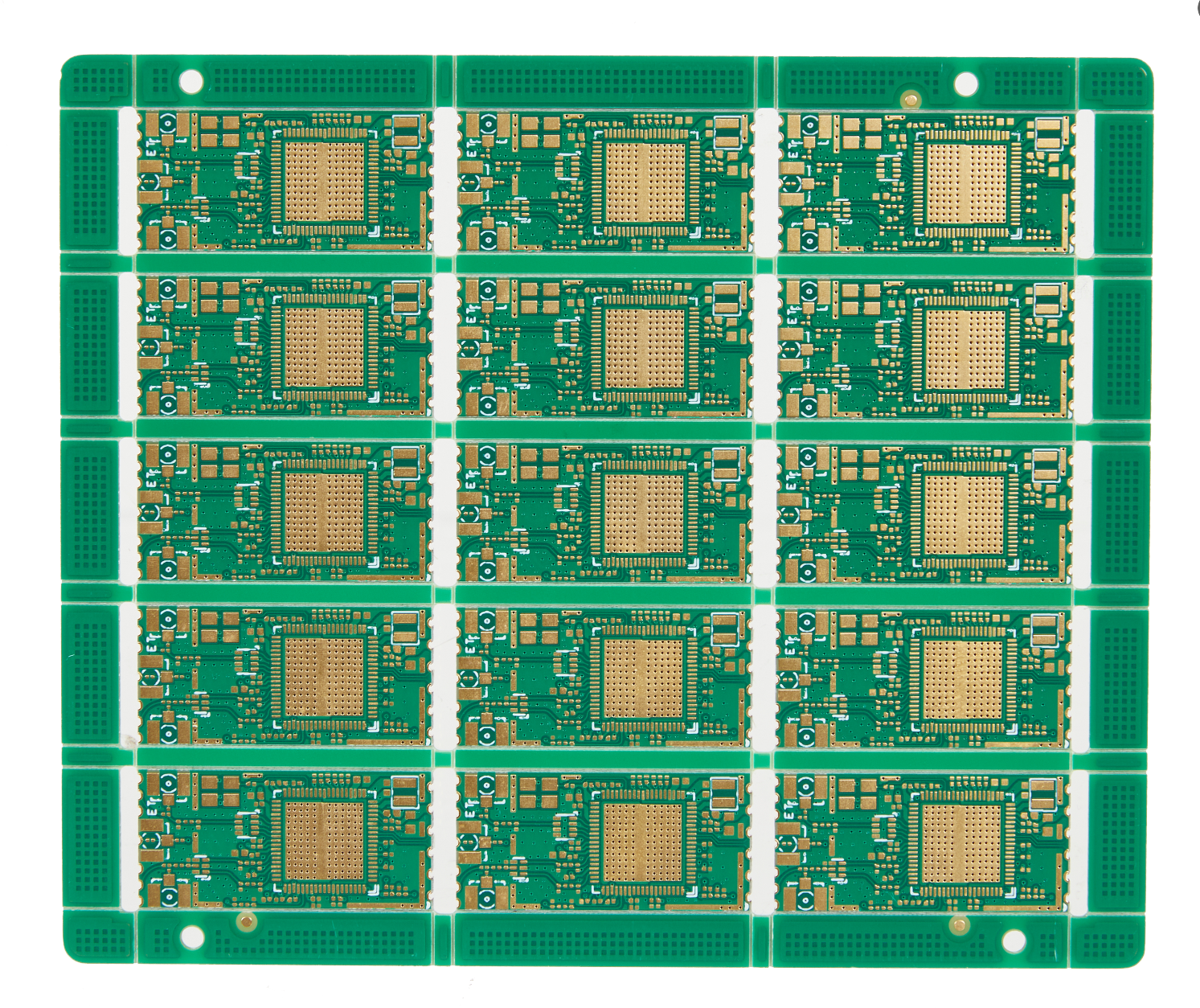

Artificial intelligence board

Product applications: smart home, security monitoring, smart door locks, mobile shelves and other fields. Floors 1 to 20 Plate thickness :0.8mm±0.1 Mechanical hole :0.2mm Minimum aperture: 0.15mm laser hole Mechanical hole :0.2mm Line width/line distance 0.1mm Surface treatment: heavy gold

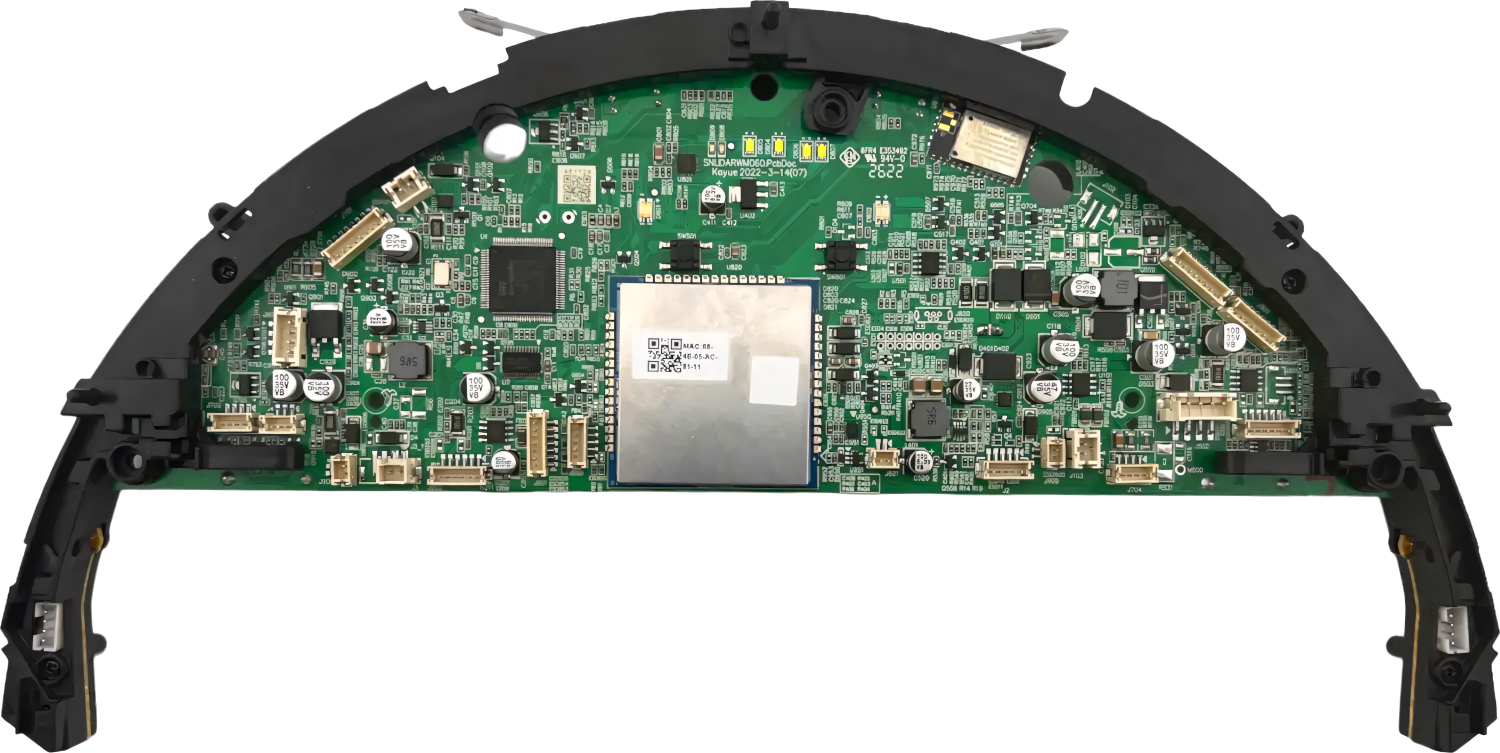

Soft and hard version

Application: Optical module, etc 6 floors, 1 level Plate thickness :1.6mm±0.16 Minimum aperture: laser hole 0.1mm mechanical hole :0.2mm Line width/line distance :0.1mm Surface treatment: heavy gold

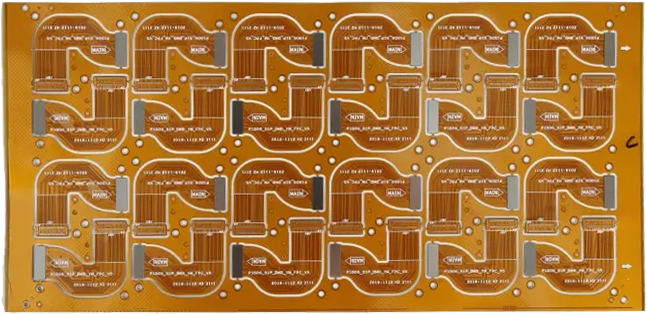

FPC soft board

Product application: soft and hard combination, FPC multi-layer board, cable, etc. 1~12 layers of calendered copper/electrolytic copper Plate thickness :1.6mm±0.16 Minimum aperture: laser hole 0.1mm Mechanical hole :0.2mm Line width/line distance :0.1mm Surface treatment: heavy gold

Rodgers mixed board with FR4

Product application: Clean technology, etc. 1~12 layers of calendered copper/electrolytic copper hole copper :20um Watch copper :35um Plate thickness :1.6mm Minimum aperture :8mil Mechanical hole :0.2mm Line width/line distance :8mil Surface treatment: heavy gold

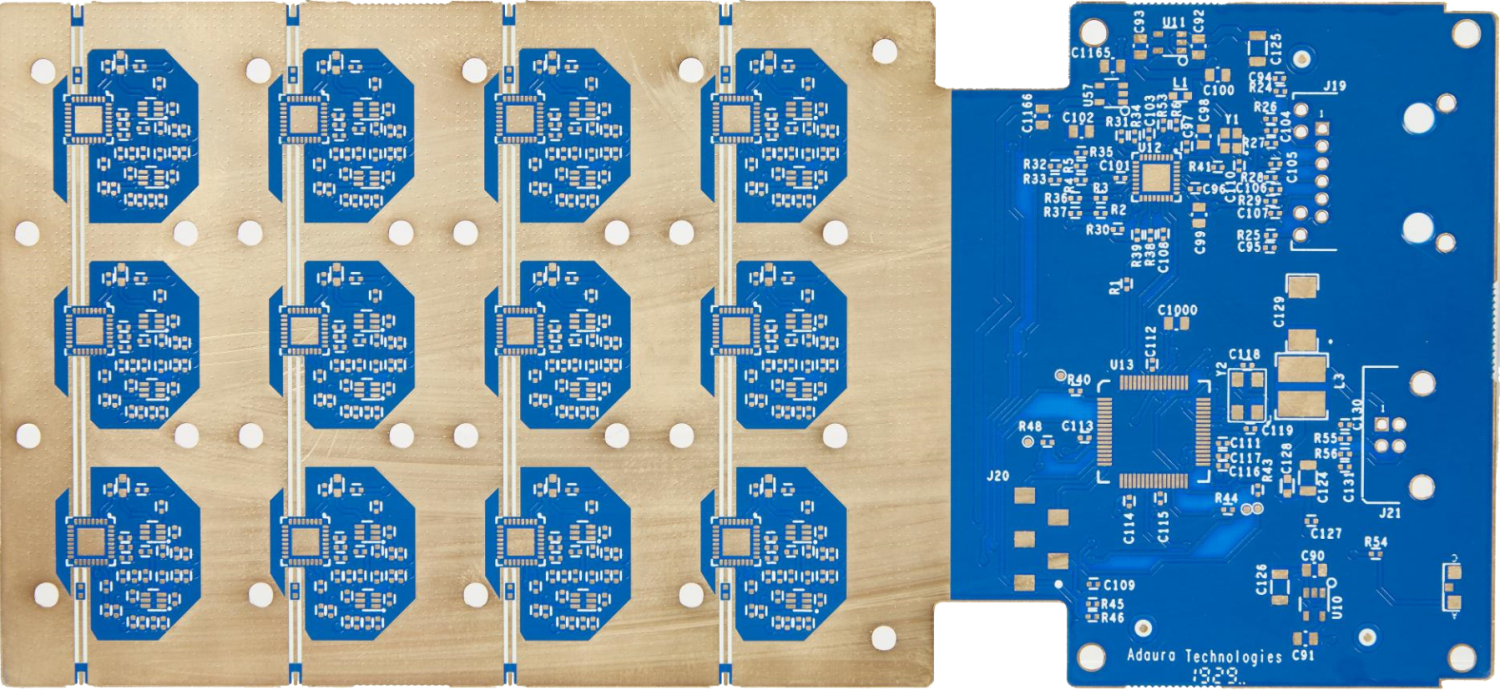

PCB Manufacturing Overview

ZYL PCB established in 2009 in Shenzhen, as one of the leading PCB manufacturer in China (100% directly operated by the factory, without any middlemen). We can offer one-stop service from PCB manufacturing to components assembling,testing and housing.We have more than 15 years of successful experience on the global EMS PCB market and enjoy high reputation in the world with on-time delivery.

Our PCB manufacturing capabilities enable us to produce a wide range of products, We can make just about any printed circuit board you can think of including HDI PCB , Multilayer PCBs (up to 40layers), High-tech PCB, Thick Copper PCB, Halogen PCB as standard options, and more special PCBs such as Rigid-Flex PCB , aluminum PCB and Rogers PCB.

For more than 15 years, we have won praises from customers all over the world with our professional product technology and high-quality service.

We will continue to upgrade our full-featured PCB services through better equipment and more efficient technology to provide customers with the highest quality full-featured PCB manufacturing and assembly. We will continue to develop and challenge ourselves and adhere to the highest quality and efficiency standards to ensure that we can help your printed circuit board use company achieve the greatest success.

PCB Manufacturing Overview

ZYL PCB established in 2009 in Shenzhen, as one of the leading PCB manufacturer in China (100% directly operated by the factory, without any middlemen). We can offer one-stop service from PCB manufacturing to components assembling,testing and housing.We have more than 15 years of successful experience on the global EMS PCB market and enjoy high reputation in the world with on-time delivery.

Our PCB manufacturing capabilities enable us to produce a wide range of products, We can make just about any printed circuit board you can think of including HDI PCB , Multilayer PCBs (up to 40layers), High-tech PCB, Thick Copper PCB, Halogen PCB as standard options, and more special PCBs such as Rigid-Flex PCB , aluminum PCB and Rogers PCB.

For more than 15 years, we have won praises from customers all over the world with our professional product technology and high-quality service.

We will continue to upgrade our full-featured PCB services through better equipment and more efficient technology to provide customers with the highest quality full-featured PCB manufacturing and assembly. We will continue to develop and challenge ourselves and adhere to the highest quality and efficiency standards to ensure that we can help your printed circuit board use company achieve the greatest success.

PCB Manufacturing Process

STEP 01

cutting

STEP 02

borehole

STEP 03

Sunk copper

STEP 04

line

STEP 05

graphics

STEP 06

etching

STEP 12

package

STEP 11

test

STEP 10

appearance

STEP 09

Surface treatment

STEP 08

character

STEP 07

Solder resist

PCB Type

PCB Surface

Common PCB surface treatment technologies that we may use in manufacturing PCBS include HASL(hot air welding flat), organic coating electroless nickel/gold plating, silver dipping, (OSP) gold dipping, etc.

Thick copper PCB

Thick copper PCBS are characterized by being covered with copper from 3 ounces to 400 microns in thickness. These PCBS are used for high current output and high thermal management. Heavy copper enables PCBS to withstand high current loads and promote heat radiation.

FR4 PCB

FR4 is the most important material in PCB assembly. Electrical engineers and technicians typically design PCB boards that use FR4 PCBS. FR4 is in high demand. FR4 printed circuit boards are plain and easy to design. FR4 PCBS are popular because they are cost-effective and can be widely used.

High strength polyethylene sheet

Generally, the Tg of FR4 is 130-140°, the medium Tg is more than 150-160°, and the high Tg is more than 170°. The higher the Tg, the better the moisture resistance, heat resistance, chemical resistance, stability and other properties of the PCB.

Certificate

Production Line

Upload File Quotation

Please leave your contact information so that we can contact you as soon as possible!

WhatsApp

WhatsApp

E-mail

E-mail