Understanding SMT PCBA: A Comprehensive Guide for Electronics Professionals

2025-08-09

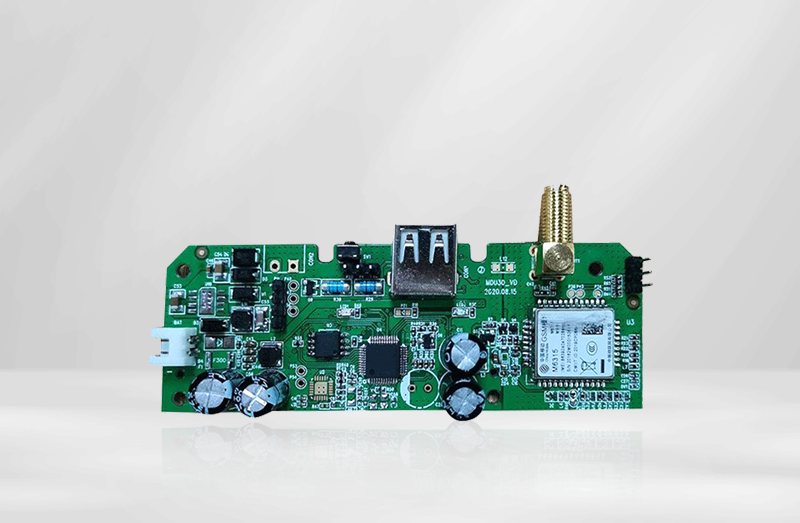

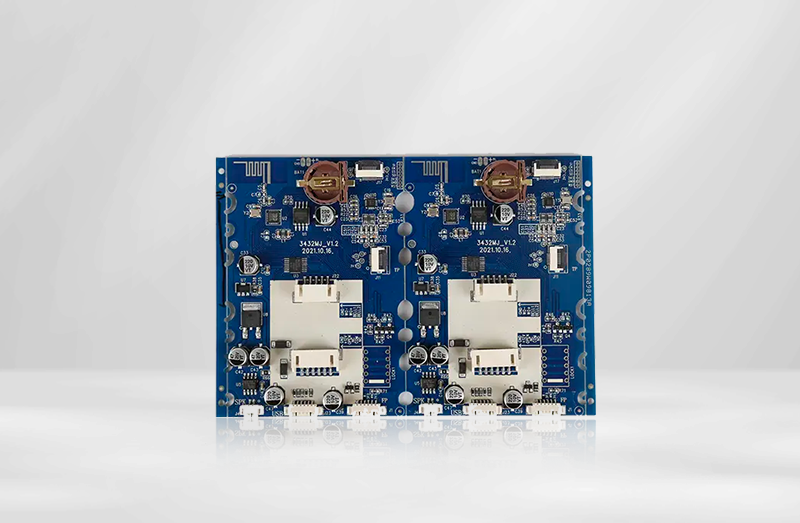

Surface Mount Technology (SMT) plays a pivotal role in the realm of Printed Circuit Board Assembly (PCBA), serving as a cornerstone for modern electronic manufacturing. SMT is a method that allows electronic components to be mounted directly onto the surface of a printed circuit board (PCB), as opposed to traditional through-hole techniques, which involve inserting leads into pre-drilled holes. This advanced technology offers several benefits, making it the preferred choice for many industries.

One of the primary advantages of SMT in PCBA is the reduction in space requirements. SMT components are typically smaller than their through-hole counterparts, allowing for more compact PCB designs. This miniaturization is especially advantageous in the ever-evolving electronics market, where devices are striving to become smaller yet more powerful, such as smartphones and wearable technology.

Another significant benefit of SMT is the efficiency it brings to the assembly process. SMT PCBA typically involves automated processes, such as pick-and-place machines that can quickly and accurately position components on the PCB. This automation not only speeds up production but also enhances the overall quality of assembly by minimizing human error. Additionally, wave soldering or reflow soldering techniques are often employed, which further streamlines the manufacturing process.

The thermal and electrical performance of SMT components is another factor contributing to their widespread adoption. SMT components generally exhibit lower inductance and capacitance, which can lead to improved signal integrity and performance in high-frequency applications. This characteristic makes SMT ideal for more advanced electronic applications, including telecommunications and computing.

In terms of design flexibility, SMT allows engineers to implement more complex circuitry within a smaller footprint. This flexibility is indispensable for innovation in product design and development. Engineers can explore various layout configurations without being constrained by the physical limitations of through-hole components.

While SMT PCBA offers numerous advantages, it is essential to be aware of potential challenges. For instance, the small size of SMT components can make them more susceptible to damage during handling and assembly. Additionally, the soldering process must be meticulously controlled to avoid issues such as solder bridging or insufficient solder joints. Implementing thorough quality control measures and utilizing skilled technicians can mitigate these risks.

In conclusion, understanding SMT PCBA is crucial for professionals in the electronics industry. The technology enhances design possibilities, improves manufacturing efficiency, and contributes to the miniaturization of electronic devices. As the demand for compact and high-performance electronics continues to grow, SMT will undoubtedly remain a significant focus in the evolution of PCB assembly processes. By harnessing the benefits of SMT, companies can stay competitive in today's fast-paced electronic landscape.

One of the primary advantages of SMT in PCBA is the reduction in space requirements. SMT components are typically smaller than their through-hole counterparts, allowing for more compact PCB designs. This miniaturization is especially advantageous in the ever-evolving electronics market, where devices are striving to become smaller yet more powerful, such as smartphones and wearable technology.

Another significant benefit of SMT is the efficiency it brings to the assembly process. SMT PCBA typically involves automated processes, such as pick-and-place machines that can quickly and accurately position components on the PCB. This automation not only speeds up production but also enhances the overall quality of assembly by minimizing human error. Additionally, wave soldering or reflow soldering techniques are often employed, which further streamlines the manufacturing process.

The thermal and electrical performance of SMT components is another factor contributing to their widespread adoption. SMT components generally exhibit lower inductance and capacitance, which can lead to improved signal integrity and performance in high-frequency applications. This characteristic makes SMT ideal for more advanced electronic applications, including telecommunications and computing.

In terms of design flexibility, SMT allows engineers to implement more complex circuitry within a smaller footprint. This flexibility is indispensable for innovation in product design and development. Engineers can explore various layout configurations without being constrained by the physical limitations of through-hole components.

While SMT PCBA offers numerous advantages, it is essential to be aware of potential challenges. For instance, the small size of SMT components can make them more susceptible to damage during handling and assembly. Additionally, the soldering process must be meticulously controlled to avoid issues such as solder bridging or insufficient solder joints. Implementing thorough quality control measures and utilizing skilled technicians can mitigate these risks.

In conclusion, understanding SMT PCBA is crucial for professionals in the electronics industry. The technology enhances design possibilities, improves manufacturing efficiency, and contributes to the miniaturization of electronic devices. As the demand for compact and high-performance electronics continues to grow, SMT will undoubtedly remain a significant focus in the evolution of PCB assembly processes. By harnessing the benefits of SMT, companies can stay competitive in today's fast-paced electronic landscape.

Related News

WhatsApp

WhatsApp

E-mail

E-mail