The Future of Electronics: Breakthrough Innovations in PCBA Assembly

2025-08-18

The Future of Electronics: Breakthrough Innovations in PCBA Assembly

Table of Contents

- 1. Introduction to PCBA and Its Importance in Electronics

- 2. Historical Overview of PCBA Assembly Techniques

- 3. Current Technologies Revolutionizing PCBA Assembly

- 4. The Role of Automation in Modern PCBA Assembly

- 5. Sustainability Practices in PCBA Assembly

- 6. Challenges Facing the PCBA Industry and Proposed Solutions

- 7. Future Trends in PCBA Assembly Technology

- 8. Conclusion: Embracing the Future of PCBA Assembly

- 9. FAQs about PCBA Assembly Innovations

1. Introduction to PCBA and Its Importance in Electronics

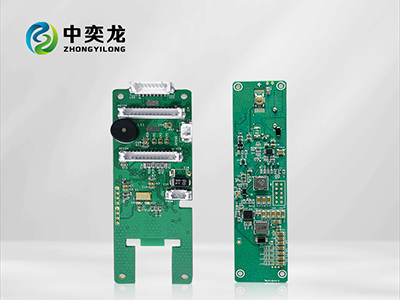

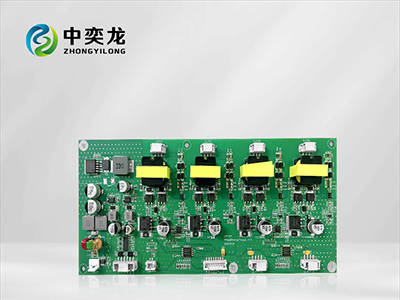

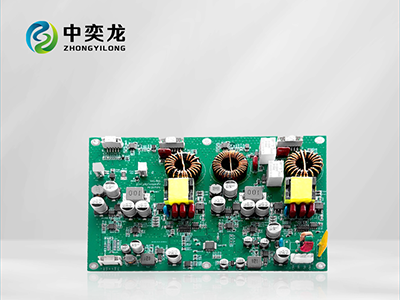

PCBA, or Printed Circuit Board Assembly, is a critical part of the electronics manufacturing process. It involves the assembly of electronic components onto a PCB to create functional electronic devices. In a world increasingly driven by technology, the significance of PCBA cannot be overstated. From smartphones to medical equipment, efficient and reliable PCBA assembly is vital for ensuring the performance and longevity of electronic devices.

One of the most exciting aspects of PCBA is its constant evolution. With innovations emerging regularly, the industry is set to experience remarkable changes in assembly techniques, materials, and processes, leading to more efficient, cost-effective, and sustainable manufacturing practices.

2. Historical Overview of PCBA Assembly Techniques

Understanding the past of PCBA assembly gives us a clearer perspective on its future. The journey began with manual assembly techniques, which were labor-intensive and time-consuming. As electronics became more complex, the need for efficient assembly methods emerged, paving the way for automated systems.

In the 1980s, surface mount technology (SMT) revolutionized the industry by allowing components to be mounted directly onto the surface of PCBs, increasing assembly density and reliability. This advancement was crucial for the miniaturization of electronic devices, enabling manufacturers to pack more functionality into smaller sizes.

The introduction of pick-and-place machines further streamlined the assembly process. These machines automate the placement of components onto PCBs, drastically reducing human error and assembly time.

3. Current Technologies Revolutionizing PCBA Assembly

Today, various technologies are reshaping the landscape of PCBA assembly. Here are some of the most notable innovations:

3.1 Advanced Robotics and AI Integration

Robots equipped with artificial intelligence (AI) are taking over repetitive tasks in PCBA assembly, ensuring precision and efficiency. These systems can learn from previous assembly processes, improving over time and adapting to new challenges.

3.2 3D Printing in PCB Prototyping

3D printing technology has made rapid prototyping of PCBs easier and more cost-effective. Engineers can quickly create and test prototypes, speeding up the design phase and reducing time-to-market for new products.

3.3 IoT and Smart Manufacturing

The Internet of Things (IoT) is revolutionizing manufacturing by enabling real-time monitoring and data collection throughout the assembly process. This connectivity leads to improved quality control and allows for predictive maintenance, minimizing downtime and maximizing production efficiency.

4. The Role of Automation in Modern PCBA Assembly

Automation plays a pivotal role in modern PCBA assembly. It enhances productivity, reduces labor costs, and improves accuracy.

4.1 Benefits of Automation

Automated systems reduce the likelihood of human error, leading to higher quality products. Furthermore, automation allows for the assembly of complex components that would be challenging to handle manually.

4.2 Implementing Automation Solutions

Implementing automation solutions requires a strategic approach. Businesses need to assess their production needs, invest in appropriate technology, and train staff to work alongside automated systems effectively.

5. Sustainability Practices in PCBA Assembly

As environmental awareness increases, the PCBA industry is adopting sustainable practices to minimize its ecological footprint.

5.1 Green Manufacturing Processes

Manufacturers are shifting towards green processes, utilizing lead-free solder and eco-friendly materials. These practices not only comply with regulations but also appeal to environmentally-conscious consumers.

5.2 Waste Reduction Techniques

Implementing waste reduction techniques, such as recycling scrap materials and reusing components, can significantly lower the environmental impact of PCBA assembly. Companies are increasingly focusing on closed-loop systems to achieve sustainability goals.

6. Challenges Facing the PCBA Industry and Proposed Solutions

While the future of PCBA assembly looks promising, several challenges need addressing.

6.1 Supply Chain Disruptions

Global supply chain disruptions can hinder the availability of crucial components. Companies can mitigate this challenge by diversifying their supplier base and adopting just-in-time inventory strategies.

6.2 Keeping Up with Rapid Technological Changes

The fast-paced evolution of technology can leave some manufacturers behind. Continuous training and investment in the latest technologies are essential for staying competitive in the market.

7. Future Trends in PCBA Assembly Technology

Looking ahead, several trends are set to dominate the PCBA assembly landscape.

7.1 Miniaturization of Components

As devices become smaller and more complex, the demand for miniaturized components will continue to rise. Manufacturers are focusing on developing smaller, more efficient components to meet this demand.

7.2 Enhanced Customization and Flexibility

The future will see an increased emphasis on customization and flexibility in assembly processes. As markets demand more personalized electronic products, manufacturers will need to adapt their assembly lines to accommodate these changes.

8. Conclusion: Embracing the Future of PCBA Assembly

The future of PCBA assembly is bright, filled with innovations that promise to enhance efficiency, sustainability, and product quality. By embracing new technologies and practices, manufacturers can position themselves favorably in a competitive market. As we move forward, staying informed about industry trends and adapting to changes will be crucial for success in the ever-evolving world of electronics.

9. FAQs about PCBA Assembly Innovations

What is PCBA?

PCBA stands for Printed Circuit Board Assembly, a process that involves attaching electronic components to a PCB to create a functioning device.

What are the benefits of automation in PCBA assembly?

Automation increases accuracy, reduces labor costs, and enhances productivity by streamlining the assembly process.

How does sustainability impact PCBA assembly?

Sustainability encourages the use of eco-friendly materials and processes, leading to a reduced environmental impact and compliance with regulations.

What challenges does the PCBA industry face?

The industry faces challenges such as supply chain disruptions, rapid technological changes, and the need for skilled labor.

What future trends should we expect in PCBA assembly?

Future trends include the miniaturization of components, enhanced customization, and increased use of smart manufacturing technologies.

By delving into these aspects of PCBA assembly, we can pave the way for a more innovative, efficient, and sustainable future in the electronics industry.

Related News

WhatsApp

WhatsApp

E-mail

E-mail