Unlocking Efficiency: The Top Benefits of Utilizing SMT PCBA in Circuit Board Manufacturing

2025-08-06

Unlocking Efficiency: The Top Benefits of Utilizing SMT PCBA in Circuit Board Manufacturing

Table of Contents

1. Introduction to SMT PCBA and Its Importance in Circuit Board Manufacturing

2. What is SMT PCBA?

3. Benefits of Using SMT in PCBA Manufacturing

3.1 Enhanced Production Speed and Efficiency

3.2 Reduced Manufacturing Costs

3.3 Improved Performance and Reliability

3.4 Space and Design Optimization

3.5 Scalability and Versatility

4. Key Applications of SMT PCBA in Various Industries

4.1 Consumer Electronics

4.2 Automotive Sector

4.3 Medical Devices

4.5 Telecommunications

5. Future Trends in SMT PCBA Technology

6. Frequently Asked Questions (FAQs)

7. Conclusion

1. Introduction to SMT PCBA and Its Importance in Circuit Board Manufacturing

In the rapidly evolving landscape of electronics, **Surface Mount Technology (SMT)** has revolutionized how we approach Circuit Board Assembly (PCBA). As manufacturers strive for **greater efficiency, reduced costs, and improved reliability**, SMT PCBA stands out as a game-changing method. This article delves deeply into the **top benefits of utilizing SMT PCBA** in circuit board manufacturing, shedding light on why this technology is a cornerstone of modern electronics production.

2. What is SMT PCBA?

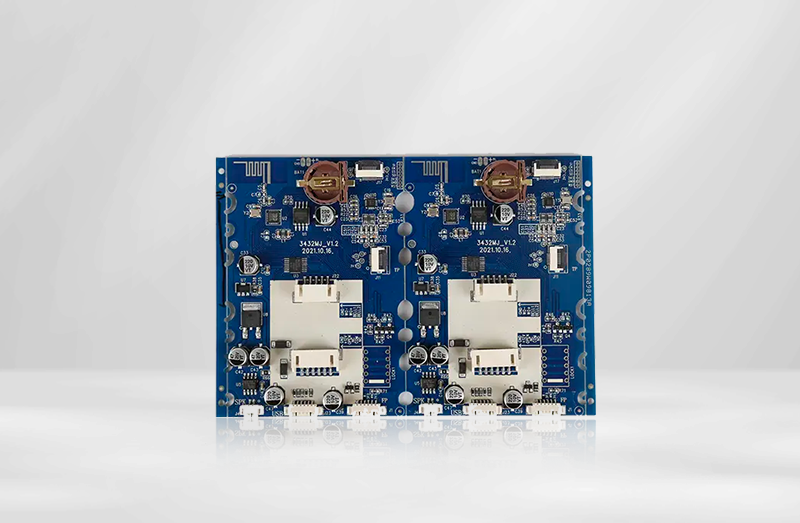

**Surface Mount Technology (SMT)** refers to the method of mounting electronic components directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole technology, where components are inserted into holes drilled in the PCB, SMT allows for a more compact arrangement of components, which is critical in today’s high-density electronics.

PCBA, or **Printed Circuit Board Assembly**, encompasses the entire assembly process, including the soldering of electronic components onto the PCB. With SMT, the process becomes faster and more efficient, enabling manufacturers to meet the rising demand for electronic devices.

3. Benefits of Using SMT in PCBA Manufacturing

3.1 Enhanced Production Speed and Efficiency

One of the primary advantages of SMT PCBA is the **remarkable increase in production speed**. The ability to place multiple components simultaneously on a PCB reduces assembly time significantly. Automated pick-and-place machines can handle a high volume of components, allowing manufacturers to scale production quickly and meet tight deadlines.

3.2 Reduced Manufacturing Costs

Incorporating SMT into the PCBA process can lead to substantial **cost savings**. With a reduced number of components needed due to their compact nature, manufacturers can lower material costs. Additionally, the streamlined assembly process results in less labor cost, making SMT a financially attractive option for electronic manufacturers.

3.3 Improved Performance and Reliability

SMT components often provide better performance due to their smaller size and lower mass. With shorter lead lengths, SMT components experience less inductance and resistance, which translates to better electrical performance. Furthermore, the soldering process in SMT provides a more robust connection, enhancing the overall **reliability** of the assembled circuit board.

3.4 Space and Design Optimization

As devices become increasingly compact, the need for **space optimization** in circuit boards has never been more critical. SMT allows for a **high component density**, enabling designers to maximize the use of limited space on the PCB. This results in thinner, lighter products that are essential in today’s competitive market.

3.5 Scalability and Versatility

SMT PCBA is highly scalable, making it suitable for both large-scale production runs and smaller batches. Manufacturers can easily adjust their operations to meet varying demand without sacrificing quality or efficiency. Moreover, the versatility of SMT allows for the integration of both passive and active components on the same board, catering to diverse electronic needs.

4. Key Applications of SMT PCBA in Various Industries

As SMT PCBA continues to gain traction, its applications span across numerous industries, demonstrating its versatility and effectiveness.

4.1 Consumer Electronics

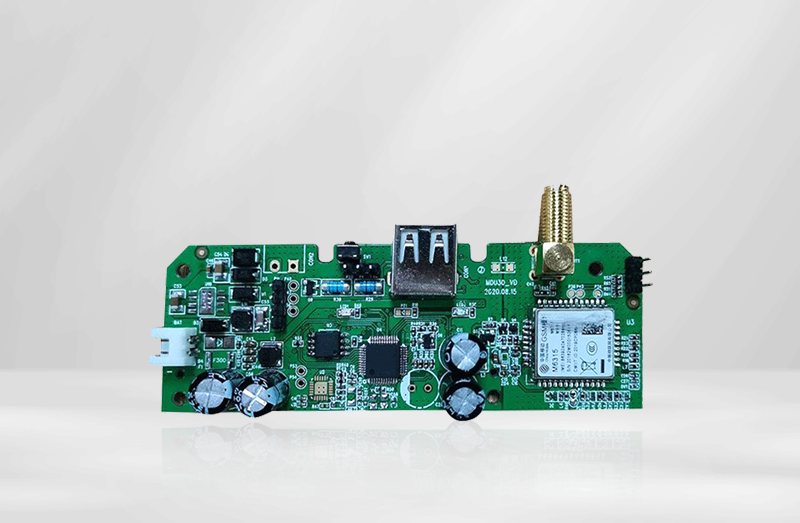

The consumer electronics industry has embraced SMT PCBA for products ranging from smartphones to home appliances. The technology’s ability to produce compact, high-quality devices has made it indispensable in this fast-paced sector.

4.2 Automotive Sector

In automotive manufacturing, SMT PCBA is critical for modern vehicles that rely heavily on electronic systems. From infotainment systems to advanced driver-assistance systems (ADAS), SMT ensures that these components are reliable and efficient.

4.3 Medical Devices

**Medical devices** require the highest standards of reliability and performance. SMT PCBA enables the production of sophisticated medical equipment that meets regulatory standards while ensuring optimal performance.

4.4 Telecommunications

Telecommunications equipment benefits from SMT PCBA through improved performance and compact designs, essential for devices like routers and smartphones that demand high-speed connectivity.

5. Future Trends in SMT PCBA Technology

The future of SMT PCBA looks promising, with ongoing innovations set to enhance its capabilities further. Key trends include:

- **Miniaturization**: As electronic devices continue to shrink, SMT will evolve to accommodate even smaller components.

- **Advanced Materials**: The use of new materials for soldering and components will improve performance and reliability.

- **Automation and AI**: Increased automation in the assembly process will drive efficiency and reduce human error, further enhancing production outcomes.

6. Frequently Asked Questions (FAQs)

What is the main difference between SMT and traditional through-hole technology?

The main difference lies in how components are mounted on the PCB. SMT components are mounted directly on the surface, while through-hole components are inserted into drilled holes.

What types of components can be used with SMT PCBA?

SMT PCBA can accommodate a wide range of components, including resistors, capacitors, integrated circuits, and connectors.

Is SMT PCBA suitable for all types of electronic products?

While SMT is versatile, its suitability depends on the product's design requirements and intended application. Generally, it is highly effective for compact and high-performance devices.

How does SMT impact the quality of circuit boards?

SMT enhances the quality of circuit boards by providing better electrical performance, reducing the risk of defects, and ensuring stronger connections.

What are the environmental impacts of SMT PCBA?

SMT PCBA can be more environmentally friendly due to less material waste and energy consumption compared to traditional methods. However, it is essential to consider the materials used and their recyclability.

7. Conclusion

In conclusion, the benefits of utilizing **SMT PCBA** in circuit board manufacturing are undeniable. From enhanced production speed and reduced costs to improved performance and design optimization, SMT technology is vital for manufacturers striving for efficiency and excellence in the competitive electronics market. As we move forward, embracing the future trends of SMT PCBA will ensure that industries remain at the forefront of innovation, meeting the ever-changing demands of consumers and technology alike.

Related News

WhatsApp

WhatsApp

E-mail

E-mail